Thordon self-lubricating bearings for industry

Thordon’s custom-made bearing shells are designed to replace greased metal bearings. Their exceptional wear resistance makes them suitable for the most demanding applications such as dusty and abrasive environments or for submerged or semi-immersed work.

Self-lubricating, dry or water-lubricated, they eliminate the risk of pollution and significantly reduce maintenance costs by offering a longer service life than other bearing materials.

The most commonly used material is ThorPlas-Blue. Finally, there is a variant of ThorPlas-Blue for food and drinking water applications: ThorPlas-White

The use of ThorPlas-Blue in new equipment also simplifies the design of assemblies by eliminating costly grease fittings. Manufacturers can therefore offer their customers clean, reliable machines with fewer maintenance requirements.

Thordon solutions: a modern, reliable and efficient response to industrial bearing problems.

Water treatment

In water treatment plants and for all industrial processes related to water, Thordon bearings have been developed to offer exceptional resistance to abrasion.

Locks machinery

Whether immersed or not, Thordon materials have demonstrated their qualities for the river industry: elimination of greasing, increased longevity, dimensional stability.

Simplified design and elimination of joint lubrication constraints on construction, operating and handling equipment.

Thordon bearings can be found in many transport applications as self-lubricating bushings on pulleys and joints.

Bulk handling

Whether for food processing or bulk transport, Thordon offers pollution-free solutions that reduce maintenance costs.

Mining and quarrying

Thordon bearings can be used in dusty environments without lubrication, offering a longer service life than other types of bearings.

Self-aligning bearings

Self-aligning spherical plain bearings are used mainly on cylinder heads and joints. They are easy to install and replace without dismantling the shaft.

Wood and paper

Abrasion and corrosion resistant Thordon bearings are ideal for forestry machines, sawmills and paper mill equipment.

A particularly efficient application has been developed in France with bearings for the sugar industry. Two examples are given below, at different stages of the process.

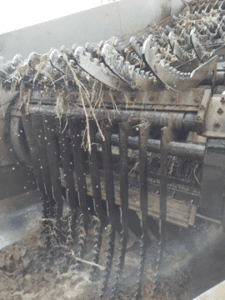

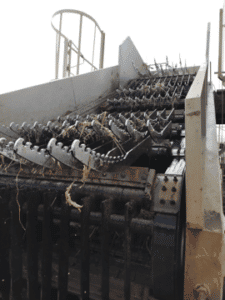

Bearings on the claws of a weed removal machine: use of SXL elastomer to replace Ertalon bearings.

The life span was multiplied by 4, the SXL bearings having lasted 2 complete campaigns where the previous bearings had to be replaced during the campaign.

The operation concerns dozens of claws. 40 “raw” tubes of one meter length were delivered and easily machined locally and crimped into the housings of the claw links.

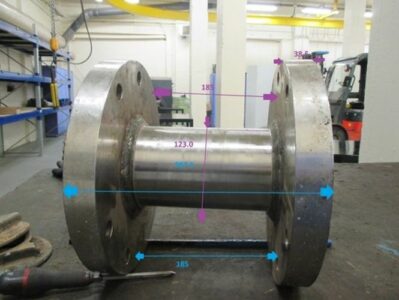

Bearings on massecuite dispenser: use of ThorPlas-White food grade thermoplastic.

Challenge: to replace the greased bronze bearings which lasted 1 or 2 campaigns and damaged the intermediate shaft (stainless steel diabolo) by a more suitable and economical material. Operating temperature 80°C.

Solution: The greased bronze bearings were replaced by ThorPlas-White greaseless bearings.

Result: The bearings lasted a full campaign with acceptable wear and no damage to the diabolo shaft.