Thordon bearings for hydro turbines

For more than 30 years, Thordon (Canada) has developed a unique expertise in lubrication-free bearings for hydroelectricity.

The principles: zero pollution, no greas or oil lubrication, water or self-lubricating, exceptional resistance to wear by abrasion.

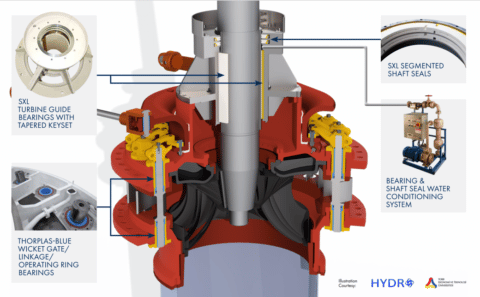

These applications concern :

- Wicket gate bearings: self-lubricating thermoplastic ThorPlas-Blue

- Main guide bearings: different types of materials depending on the quality of the water, from very heavy alluvial water, the GM2401 composite, to filtered or moderately heavy water, the SXL.

- Axial or radial seals: in SXL elastomer with many advantages over carbon seals.

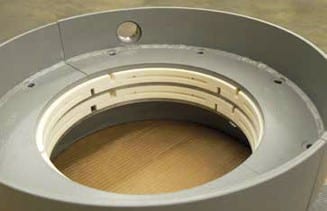

Main guide bearings

Thordon Bearings recommends two categories of bearings for use in turbine water-lubricated main guide bearings:

- Thordon SXL offers the lowest coefficient of friction, superior adhesive wear performance and good resistance to abrasion from third-party particles.

- Thordon GM2401 is specially formulated to provide superior wear resistance in abrasive-laden water conditions exceeding the life of rubber bearings by a ratio of two or more, while providing a significantly lower coefficient of friction than rubber bearings.

ThorPlas-Blue bearings for wicket gates, Kaplan hubs and drive mechanisms

ThorPlas-Blue is recommended for wicket gates bearings and drive mechanisms bearings. It is also well suited for Kaplan turbine blade hub bearings. It is an engineered thermoplastic with ideally balanced performance for these applications:

- high load carrying capacity, which generally allows for side-by-side replacement of bronze bushings.

- at the same time, an excellent resistance to abrasive wear, far superior to that of bronze or even to thermo-laminated products that can still be found, ThorPlas-Blue being less “stiff”.

- perfect material homogeneity.

- a low friction coefficient.

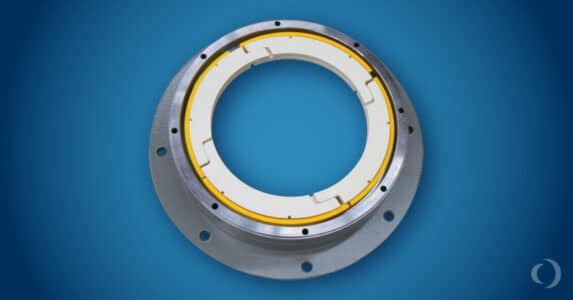

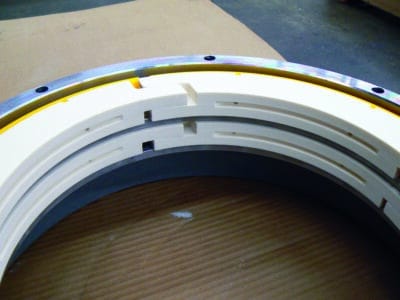

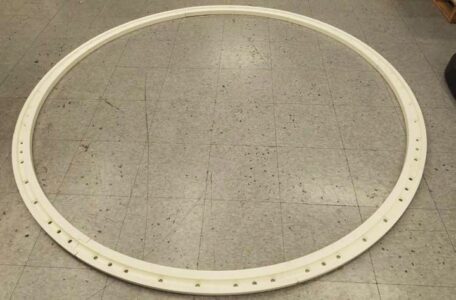

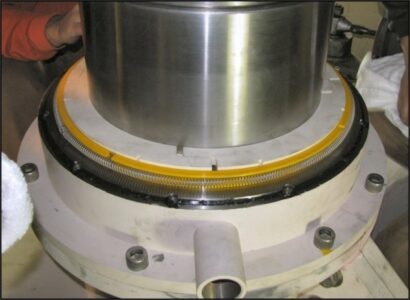

Joints d’arbre segmentés

Assurer l’étanchéité d’arbre de grandes turbines hydrauliques de 40cm à plus de 2m de diamètre peut devenir un challenge pour les opérateurs de centrales. Typiquement, les joints de turbines consistent en deux ou trois jeux empilés d’anneaux au carbone qui sont difficiles à installer sans casser et peuvent être l’objet d’une relativement faible durée de vie en cas de mauvais alignement ou soumis à des abrasifs.

Depuis sa première installation en 1982 à la centrale de Manapouri en Nouvelle Zélande, Thordon Bearings a accumulé un important historique d’installations de joints d’arbre segmentés. En 2003, Thordon a réalisé un programme d’optimisation de ses étanchéités segmentées avec son matériau SXL.

Le SXL est un élastomère synthétique offrant une installation aisée, une résistance naturelle à l’abrasion élevée et de très bonnes performances d’étanchéité.